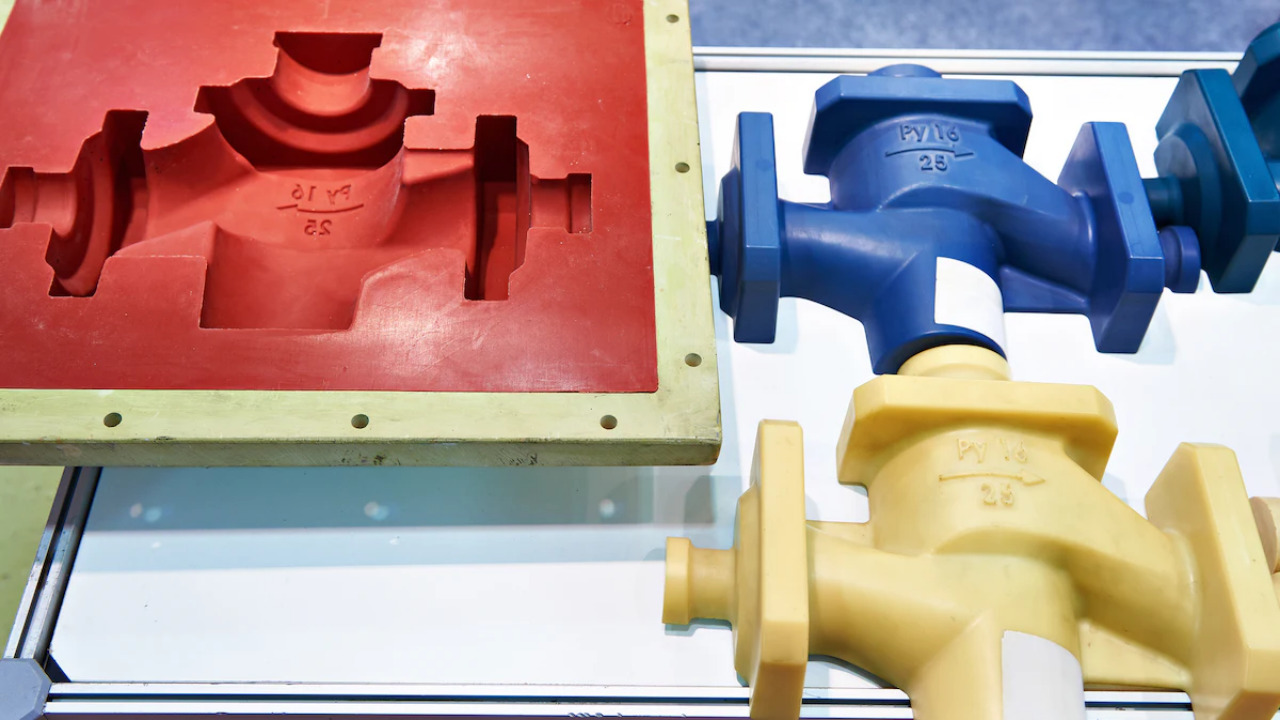

Plastic injection molding is one of the most popular manufacturing processes worldwide. It is a widely-used technique for producing plastic parts in large quantities. This process involves injecting molten plastic into a mold cavity to create a specific shape or design. The mold is then cooled, and the plastic part is ejected from the mold.

Plastic injection molding service is popular for the following reasons:

Versatility

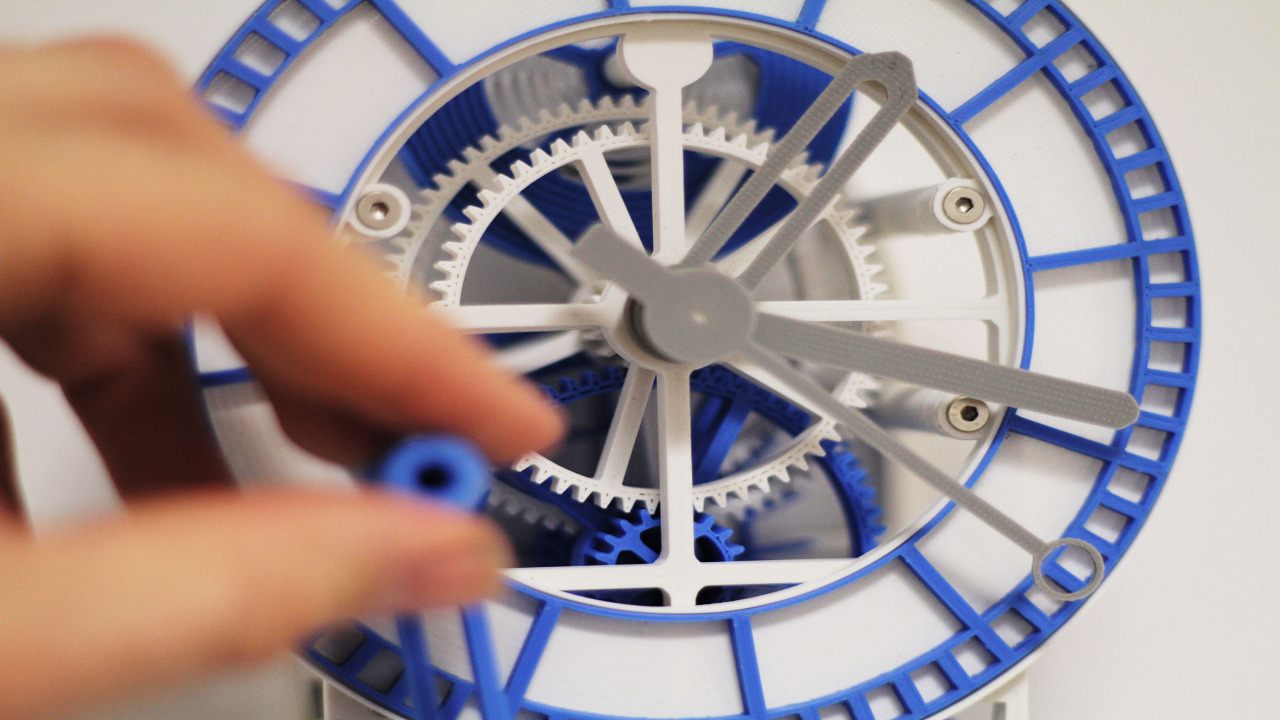

One of the primary reasons is its versatility. It can be used to produce parts in a wide variety of sizes, shapes, and designs. This is because the mold can be customized to the specific requirements of each part, allowing for precise control over the final product. This makes it ideal for manufacturing complex parts with intricate designs.

Efficiency

Another reason why plastic injection molding is so popular is its efficiency. Once the mold is created, the production process can be automated, allowing for the high-volume production of identical parts. This results in a fast and cost-effective manufacturing process that can produce large quantities of parts in a short amount of time.

Precision and Accuracy

In addition, plastic injection molding is ideal for producing parts with high precision and accuracy. The process allows for tight tolerances and minimal waste, resulting in consistent, high-quality parts that meet exact specifications. This is particularly important for industries such as aerospace, medical, and automotive, where precision and accuracy are crucial.

A Wide Range of Material Options

Plastic injection molding is also a popular choice because it offers a wide range of material options. There are various types of plastic materials available, including thermoplastics, thermosetting plastics, and elastomers. Each type of plastic material has its own unique properties, such as durability, flexibility, and heat resistance. This allows manufacturers to choose the best material for each specific application, ensuring that the finished product meets the required performance standards.

Design Flexibility

The process of plastic injection molding also offers a high degree of design flexibility. It allows for the creation of intricate and complex shapes, such as internal threads, undercuts, and overhangs. This means that designers and engineers can create parts that would be difficult or impossible to produce using other manufacturing processes.

Sustainability

Furthermore, plastic injection molding is a sustainable manufacturing process. Many plastic materials used in injection molding are recyclable, and the production process itself generates minimal waste. This means that manufacturers can reduce their environmental impact and contribute to a more sustainable future.

Cost-Effectiveness

Finally, plastic injection molding services are popular because they offer cost-effective solutions for manufacturing plastic parts. The process is highly efficient and can produce large quantities of parts quickly and accurately, reducing production costs. Additionally, the ability to customize molds means that manufacturers can produce parts with minimal waste, further reducing costs.

Conclusion

In conclusion, plastic injection molding services are popular because they offer a range of benefits, including versatility, efficiency, precision, material options, design flexibility, sustainability, and cost-effectiveness. These advantages make it a popular choice for a wide range of industries, from automotive and aerospace to medical and consumer goods. With ongoing advancements in technology and materials, plastic injection molding is likely to remain a popular manufacturing process for many years to come.